high density fibreboard

medium density fibre board

film faced plywood

veneered boards

mdf board

mdf wood fiberboard

what is mdf

mdf sheets

mdf medium density fibreboard

particle board

waterproof mdf

hardboard

birch plywood

plywood sheets

laminated plywood

plywood costs

mdf plywood

chipboard

melamine sheets

mdf board sizes

mdf suppliers

laminated mdf

mdf panel melamine

plywood manufacturers

mdf sheet

melamine board

mdf board suppliers

water resistant mdf

mdf manufacturers

mdf mouldings

exterior plywood

mdf board thickness

laminated mdf board

veneered mdf sheets

|

production MDF Pakistan

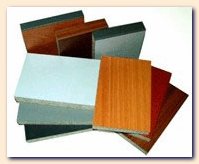

Name: - Medium Density Fibreboard ( MDF )

Sources: - MDF is a type of hardboard, which is made from wood fibres glued under heat and pressure.

Advantages: - There are a number of reasons why MDF may be used instead of plywood or chipboard. It is dense, flat, stiff, has no knots and is easily machined. Because it is made up of fine particles it does not have an easily recognisable surface grain. MDF can be painted to produce a smooth quality surface. Because MDF has no grain it can be cut, drilled, machined and filed without damaging surface. MDF may be dowelled together and traditional woodwork joints may even be cut. MDF may be glued together with PVA wood glue. Oil, water-based paints and varnishes may be used on MDF. Veneers and laminates may also be used to finish MDF

Disadvantages: - MDF can be dangerous to use if correct safety precautions are not taken. MDF contains a substance called urea formaldehyde, which may be released from material through cutting and sanding. Urea formaldehyde may cause irritation to eyes and lungs. Proper ventilation is required when using it and facemasks are needed when sanding or cutting MDF with machinery. dust produced when machining MDF is very dangerous. Masks and goggles should always be worn at all times. Due to fact that MDF contains a great deal of glue cutting edges of your tools will blunt very quickly. MDF can be fixed together with screws and nails but material may split if care is not taken. If you are screwing, screws should not be any further than 25mm in from edge. When using screws always use pilot holes. Urea formaldehyde is always being slowly released from surface of MDF. When painting it is good idea to coat whole of product in order to seal in urea formaldehyde. Wax and oil finishes may be used as finishes but they are less effective at sealing in urea formaldehyde

Uses: - It may be used to make display cabinets, wall-panels and storage units.

Large-scale production of MDF began in 1980s. Its name derives from distinction in densities of fibreboard. MDF typically has a density of 600-800 kg/m?. Particle board is a low-density fibreboard and has a density of 160-450 kg/m?, while hardboard, also called high-density fibreboard, has a density of 500-1,450 kg/m?. Similar manufacturing processes are used in making all types of fibreboard.

|

Hardboards Pakistan

| Density , kg/cubic meter :

HB-HT : 650-850

TC : 850-950

Fibre board,mark HB-HT,TC: one surface smooth, produced by a wet process.

Fibre board,mark TCH-30 : both surface smooth, produced by a dry process.

Class of emission of formaldehyde - E1 |

Hardboards / HDF

|

| |

|

| Thickness, mm | Width, mm | Length, mm | The size, m2 / Sheet | Price USD / m2 | Price USD / Sheet |

Hardboard

MDF 3,2 | 2140 | 1220 | 2,61 | 0,64 | 1,7 |

Hardboard

MDF 3,2 | 2140 | 2470 | 5,29 | 0,64 | 3,4 |

Hardboard

MDF 3,2 | 2745 | 1700 | 4,67 | 0,64 | 3,0 |

MDF - Medium Density Fibreboard Pakistan

MDF ( Medium Density Fibreboard )

|

|

| Thickness, mm | Width, mm | Length, mm | The size, m2 / Sheet | Price USD / m2 | Price USD / Sheet |

Medium Density Fibreboard

MDF 2,5 | 2440 | 1220 | 2,98 | 0,60 | 1,8 |

Medium Density Fibreboard

MDF 2,5 | 2440 | 1845 | 4,50 | 0,60 | 2,7 |

Medium Density Fibreboard

MDF 2,5 | 2440 | 1830 | 4,47 | 0,60 | 2,7 |

Medium Density Fibreboard

MDF 2,5 | 2500 | 1230 | 3,08 | 0,60 | 1,8 |

Medium Density Fibreboard

MDF 3,0 | 2440 | 1220 | 2,98 | 0,72 | 2,1 |

Medium Density Fibreboard

MDF 3,0 | 2440 | 1845 | 4,50 | 0,72 | 3,2 |

Medium Density Fibreboard

MDF 3,0 | 2440 | 1830 | 4,47 | 0,72 | 3,2 |

Medium Density Fibreboard

MDF 3,0 | 2500 | 1230 | 3,08 | 0,72 | 2,2 |

Medium Density Fibreboard

MDF 3,2 | 2440 | 1220 | 2,98 | 0,77 | 2,3 |

Medium Density Fibreboard

MDF 3,2 | 2440 | 1845 | 4,50 | 0,77 | 3,5 |

Medium Density Fibreboard

MDF 3,2 | 2440 | 1830 | 4,47 | 0,77 | 3,4 |

Medium Density Fibreboard

MDF 3,2 | 2500 | 1230 | 3,08 | 0,77 | 2,4 |

Medium Density Fibreboard

MDF 3,6 | 2440 | 1220 | 2,98 | 0,86 | 2,6 |

Medium Density Fibreboard

MDF 3,6 | 2440 | 1845 | 4,50 | 0,86 | 3,9 |

Medium Density Fibreboard

MDF 3,6 | 2440 | 1830 | 4,47 | 0,86 | 3,9 |

Medium Density Fibreboard

MDF 3,6 | 2500 | 1230 | 3,08 | 0,86 | 2,7 |

Medium Density Fibreboard

MDF 4,0 | 2440 | 1220 | 2,98 | 1,0 | 2,9 |

Medium Density Fibreboard

MDF 4,0 | 2440 | 1845 | 4,50 | 0,96 | 4,3 |

Medium Density Fibreboard

MDF 4,0 | 2440 | 1830 | 4,47 | 0,96 | 4,3 |

Medium Density Fibreboard

MDF 4,0 | 2500 | 1230 | 3,08 | 0,96 | 3,0 |

Medium Density Fibreboard

MDF 5,0 | 2440 | 1220 | 2,98 | 1,20 | 3,6 |

Medium Density Fibreboard

MDF 5,0 | 2440 | 1845 | 4,50 | 1,20 | 5,4 |

Medium Density Fibreboard

MDF 5,0 | 2440 | 1830 | 4,47 | 1,20 | 5,4 |

Medium Density Fibreboard

MDF 5,0 | 2500 | 1230 | 3,08 | 1,20 | 3,7 |

Melamine-faced MDF Pakistan

Melamine-faced MDF ( structure - "Grajeewo" )

|

|

| Thickness, mm | Width, mm | Length, mm | The size, m2 / Sheet | Price USD / m2 | Price USD / Sheet |

| Melamine MDF 2,5 | 2440 | 1220 | 2,98 | 1,50 | 4,5 |

| Melamine MDF 2,5 | 2440 | 1845 | 4,50 | 1,50 | 6,8 |

| Melamine MDF 2,5 | 2440 | 1830 | 4,47 | 1,50 | 6,7 |

| Melamine MDF 2,5 | 2500 | 1230 | 3,08 | 1,50 | 4,6 |

| Melamine MDF 3 | 2440 | 1220 | 2,98 | 1,80 | 5,4 |

| Melamine MDF 3 | 2440 | 1845 | 4,50 | 1,80 | 8,1 |

| Melamine MDF 3 | 2440 | 1830 | 4,47 | 1,80 | 8,0 |

| Melamine MDF 3 | 2500 | 1230 | 3,08 | 1,80 | 5,5 |

| Melamine MDF 3,2 | 2440 | 1220 | 2,98 | 1,92 | 5,7 |

| Melamine MDF 3,2 | 2440 | 1845 | 4,50 | 1,92 | 8,6 |

| Melamine MDF 3,2 | 2440 | 1830 | 4,47 | 1,92 | 8,6 |

| Melamine MDF 3,2 | 2500 | 1230 | 3,08 | 1,92 | 5,9 |

| Melamine MDF 3,6 | 2440 | 1220 | 2,98 | 2,16 | 6,4 |

| Melamine MDF 3,6 | 2440 | 1845 | 4,50 | 2,16 | 9,7 |

| Melamine MDF 3,6 | 2440 | 1830 | 4,47 | 2,16 | 9,6 |

| Melamine MDF 3,6 | 2500 | 1230 | 3,08 | 2,16 | 6,6 |

| Melamine MDF 4 | 2440 | 1220 | 2,98 | 2,4 | 7,1 |

| Melamine MDF 4 | 2440 | 1845 | 4,50 | 2,40 | 10,8 |

| Melamine MDF 4 | 2440 | 1830 | 4,47 | 2,40 | 10,7 |

| Melamine MDF 4 | 2500 | 1230 | 3,08 | 2,40 | 7,4 |

| Melamine MDF 5 | 2440 | 1220 | 2,98 | 3,00 | 8,9 |

| Melamine MDF 5 | 2440 | 1845 | 4,50 | 3,00 | 13,5 |

| Melamine MDF 5 | 2440 | 1830 | 4,47 | 3,00 | 13,4 |

| Melamine MDF 5 | 2500 | 1230 | 3,08 | 3,00 | 9,2 |

Development of market of wood plates from MDF and OSB Pakistan

As is known, consumption and manufacture of wood plates in world are constantly increased. greatest rates of growth have wood-fiber plates of average density ( MDF plates, Melamine MDF ), used in furniture manufacture and at realization of painting and decorating in all types of premises(rooms), and plates from Sizable a focused shaving (Lam OSB plates). Plate MDF ( Medium density fibreboard )is made by a method of pressing of wood fibres with use organic binding in conditions of a high pressure and temperatures. To manufacturing plates MDF it is applied, as

Rule, low-grade wood and waste products woodmanufacture. Plate MDF, Melamine-faced MDF has one

Native dense structure due to what by opportunities of machining she(it) it is significant

Surpasses a natural tree. Especially it is necessary to note, that by manufacture MDF of plates persons of pitch dangerous to health and phenols, that is an end-product are not used

It turns out non-polluting.

Capacities on manufacture of wood plates MDF all world make more than 140 million cube in one year where on a share of Russia and Belarus it is necessary 2,3 %. On statistics capacity of manufacture of wood plates in 2002 in Russia had following parameters: OSB - 2,731 million cube. M: MDF - 0,281 million cube. M; Lam OSB a plate - 0 and in a result - 3,012 million cube. M. As comparison: in Northern America total amount of manufacture was on order more than in Russia and Byelorussia. Such parameters at presence of richest wood resources are smallest. Besides up to 50 % of wood plates not Correspond to modern requirements on quality and on specific expenses for manufacture, it is limited a number(line) of plates, capacities on laminated are insufficient. Thus it is known, that woods of Russia have a plenty of low-grade wood, not suitable for pulp-and-paper manufacture, but which raw material for manufacturing various wood plates MDF, OSB and Lam OSB

Now annual waste products wood manufactures make more than 140 million cube and

Quite may form a basis " for intensive development of manufacture of wood plates.

Conducting West-European firms already have estimated perspectivity of an investment of means in construction of own factories on manifacture wood plates OSB and MDF in Russia. Attractive is blank

The Russian market on OSB, MDF and Lam OSB to plates. Lack in Russian market boards materials of an optimum parity(ratio) cost - quality will be filled already in near future due to commissioning of factories of various capacity equipped with modern equipment.

Among first on Russian market there came Austrian companies. Now for manufacture of plates MDF and OSB, basically, uses coniferous breeds of wood due to what plate has a soft yellowish shade. As raw material wood of poor quality, as a rule, is applied to manufacture of plates, so-called technological wood, and also - waste products wood manufactures ( wood bark ), that is that

Product which for today practically does not find to itself application.

Plates MDF are used for manufacturing decorative furniture facades, ideally approach for creation of a skeleton of various subjects of furniture, and also - for furnish of an interior, such as panel, dekor rods, plinths, structures, table-tops. To expand sphere of application it was possible due to introduction of an additional stage in process of manufacture of a plate: wood - clears of a bark that provides to it(her) a homogeneous light shade and homogeneous structure at which processing there will be no infringement of integrity of a surface because of presence a bark, besides production has equally light color. This one of main advantages of technology before manufacturers of plates MDF.

Except for it it is made panels for facing walls and structures. And at an exhibition laminated floor coverings and panels made on basis MDF and OSB of a plate were submitted.

Exhibiting of laminated floor of Russian manufacture for visitors was present sensation, you see before laminated was imported exclusively from abroad.

Begun positive changes in sphere wood facilities(economy) of Russia already become tendency, that at once has an effect for market offer. At presence of a growing demand for qualitative production from plate MDF, Melamine MDF, Russia gradually turns to supplier of high quality products from wood with big opportunities and prospects. And this tendency is obvious not only to experts and leaders of branch.

|

|